Where classic OEE

fails

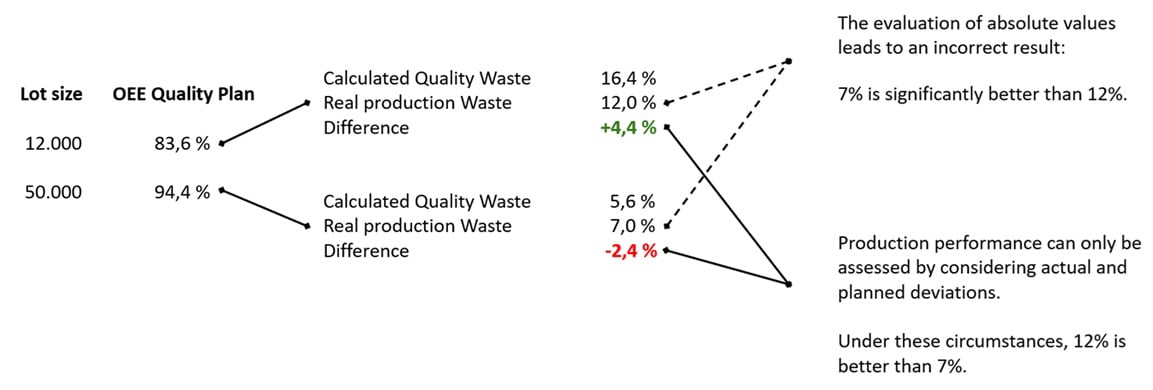

Classic OEE becomes misleading when different products require different setup times, speeds, and scrap rates.

In high mix production, OEE can change simply because the order mix changes, even if production performance stays the same.

When planned losses result from commercial decisions, aggregated OEE cannot separate these effects from real production losses.

As a result, OEE trends no longer reflect production performance.